The balls in the mill are in a variety of sizes, which wear out over a period of time and need to be screened and recharged.

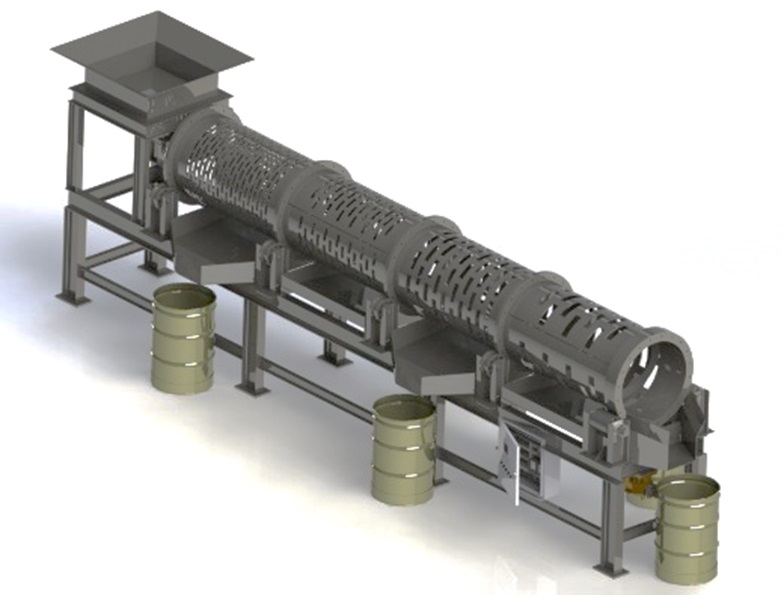

The presented product is used to screen the size of metal balls in the mining industry and has a ball inlet tank with a capacity of 2 tons per moment and the ability to separate balls up to 150 mm in size in 2 to 6 outlets.

The device weighs approximately 1300 kg and its dimensions are 2700x1500x3900 mm.

In this device, the ball transmission path has a vibration motor to prevent path clogging and the isolating mesh drum made of anti-wear which can be replaced. A simple user interface is also provided for the device operator to command.

In addition to the above, the following features can also be added to the basic sample:

– washing and cleaning the balls during the separation process

– separating of balls with spherical surface and balls with worn and hollow surface

– barrel discharge system from the ground into the feed tank of the device

– weighing system and ball counter and control panel to display information

– portability of the device set

This machine is suitable for ball mills and semi-autogenous.