Home> Projects > Special Equipment > Heavy Industrial Gearbox

Gearboxes are power transmission systems, with changing the speed, torque, direction of rotation, or changing angle of rotation. Gearboxes covert input torque and speed to required output ones. DSDA is capable of designing, manufacturing, and testing of gearboxes in a wide range of power.

During the gearbox design process, in addition to mechanical, vibrational, and thermal designs, all peripheral equipment and standard parts used in the gearbox are going to select or design accordingly.

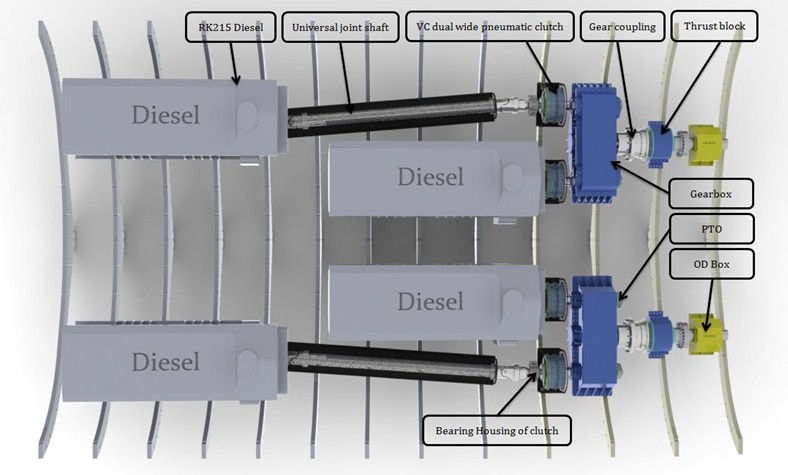

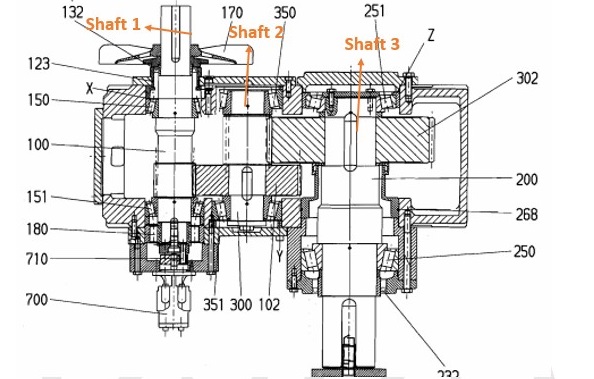

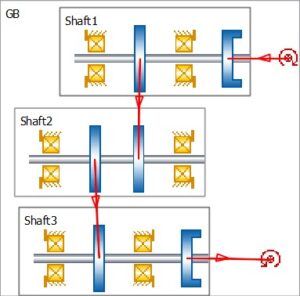

Design of 2 MW gearbox for wind turbine and 7.5 MW CODAD gearbox are among the designed projects in DSDA company.

Troubleshooting, life expectancy estimation, and optimization of industrial gears are other services provided by DSDA Company in this field. These inspections prevent unforeseen failures in various systems that cause heavy costs for factories. Also, in factory development projects, the final power of the gearbox is checked and its lifespan is calculated with the new nominal capacity.

To check the correct operation of the gearbox, there is also the design, construction, and commissioning of a gearbox test rig in various capacities. A car gearbox testing machine is an example of the project implemented by DSDA company in this field.

Durali System Design and Automation company is capable of designing of custom gearbox for a wide range of powers in various fields.